For many Original Equipment Manufacturers, finding companies that can offer parts manufacturing at a low cost per unit and with efficiency and reliability is a challenge. Often large machining shops prioritize customer orders on volume, where the larger customers get their production runs moved to the front of the line.

There may also be some shops that have very high minimum numbers of units per order in order to get the best pricing. There may even be different options in manufacturing options that the company offers as a way to keep costs down and speed up production.

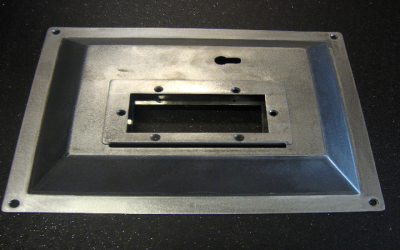

However, one process they won’t offer is metal stamping. As a specialized process to create simple to complex shapes from sheet metal, it is highly cost-effective, has extremely limited waste and offers full quality control and production to tight tolerances. Metal stamping companies tend to only provide this process as it requires specialized equipment and trained engineers and operators.

Metal stamping can also be used with a variety of sheet metals. It is an ideal solution for parts in brass, copper and stainless steel as well as carbon steel.

Comparing Options

OEMs in the aerospace and automotive industries as well as in HVAC system manufacturing and even metal building construction should consult with metal stamping companies and compare costs, turnaround time and value-added services.

Between different metal stamping companies, there can be significant differences and it is essential to ensure there is a similar comparison for quality control, production capability, and any additional services request.

Not all metal stamping services offer finishing services for plating parts, but other companies will offer this through subcontractors. As a way to streamline the production process and reduce logistics issues, this can be an ideal option to consider for any size of OEM.