Every day, metal is fabricated and made into numerous items both large and small. These items could be structural components of a building or a small decorative item for the home. Either way, fabricators often used varied techniques to achieve the desired result.

Engineering fabrication is commonly used in the automotive industry and in manufacturing among other industries. While many methods are used to work with metal, the three below are among the more common examples.

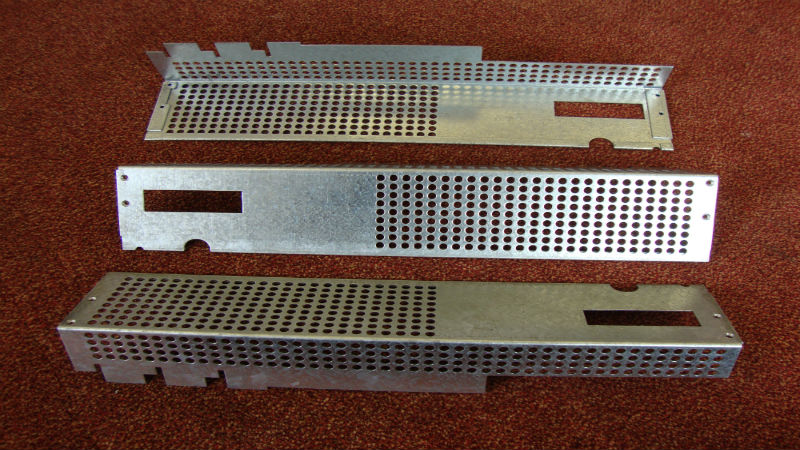

Metal Cutting

Some products or items may be cut from large sheets of steel or other metals. Cutting is, therefore, a useful engineering fabrication method to cut down the sheets into smaller and more manageable sections to work with. Sometimes, more than one pass through a cutting machine may be required to attain the desired outcome.

Machining

While cutting reduces the size of a piece of metal, machining allows someone to remove sections from that piece. For instance, an L-shape may be needed, or alternatively a far more complex shape. In such cases, machining would be used to reach the final shape required.

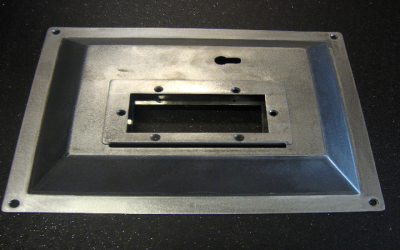

Casting

While the above methods involve machinery and solid metal pieces, casting involves heating the metal until it reaches its molten state. If a challenging shape or form is required to be made, casting is often the best method for achieving this. A mould will be made ahead of the casting process. The metal is then melted and poured into it, before being left to solidify once again. This engineering fabrication method, in common with all other fabrication methods, requires the highest degree of safety to ensure no injuries are experienced.

Steel and other metals are everywhere in the world around us. Some products may need more attention than others during the fabrication process, so they reach the desired shape and outcome.