Preventive maintenance can help keep your baler operations smooth and trouble-free. Take a look at some of the things you should know about baler preventive maintenance:

Common preventive tasks

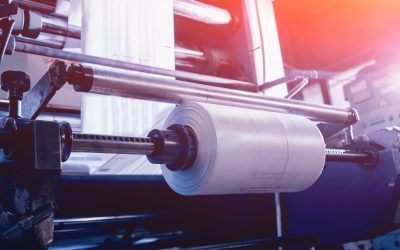

This generally involves cleaning behind the rams. The sensors should also be cleaned and the breather filters replaced with new ones. Don’t forget to check out the oil cooler to clear out any of the dust and debris that might have find their way into the cooler. In addition, make sure you take a look at the condition of your baler belts.

Look out for signs of trouble

If anything looks too worn or there are leaks, those are signs you need to replace parts in your machine. One of the parts that regularly suffer from constant abuse is your baler belt. So check if yours is already too loose or looks ready to snap. Install a replacement before the problem gets worse.

Stop problems from growing

f you don’t take the time and effort to perform preventive maintenance tasks, this could result in a lot of wear and tear for your machine parts, says Recycling Today. Also, maintenance checks catch issues before they become bigger problems. So without those checks, problems would go unresolved, giving you even bigger trouble to deal with in the future.

Get quality parts

Browse through baler belts for sale and go with picks from credible sources and brands. Going for parts that are a step-down in quality could hurt your machine’s operations and result in delays in your schedule. Also, go for reputable sources. That way, you’re sure to get parts you can you trust.

Considering how much balers cost, you’d want to make sure yours last you a long time. So regularly perform preventive measures. And replace anything that’s worn or loose to keep your machine in top form.