For food and beverage manufacturers in the United States, maintaining efficiency and product quality is more critical than ever. As consumer expectations and regulatory standards continue to evolve, companies must seek innovative solutions to optimize their production processes. One technology that has become indispensable for modern factories is Vibrating Sifters. These advanced machines play a pivotal role in streamlining production, boosting throughput, and ensuring product consistency across a wide range of food and beverage applications.

Enhancing Production Efficiency

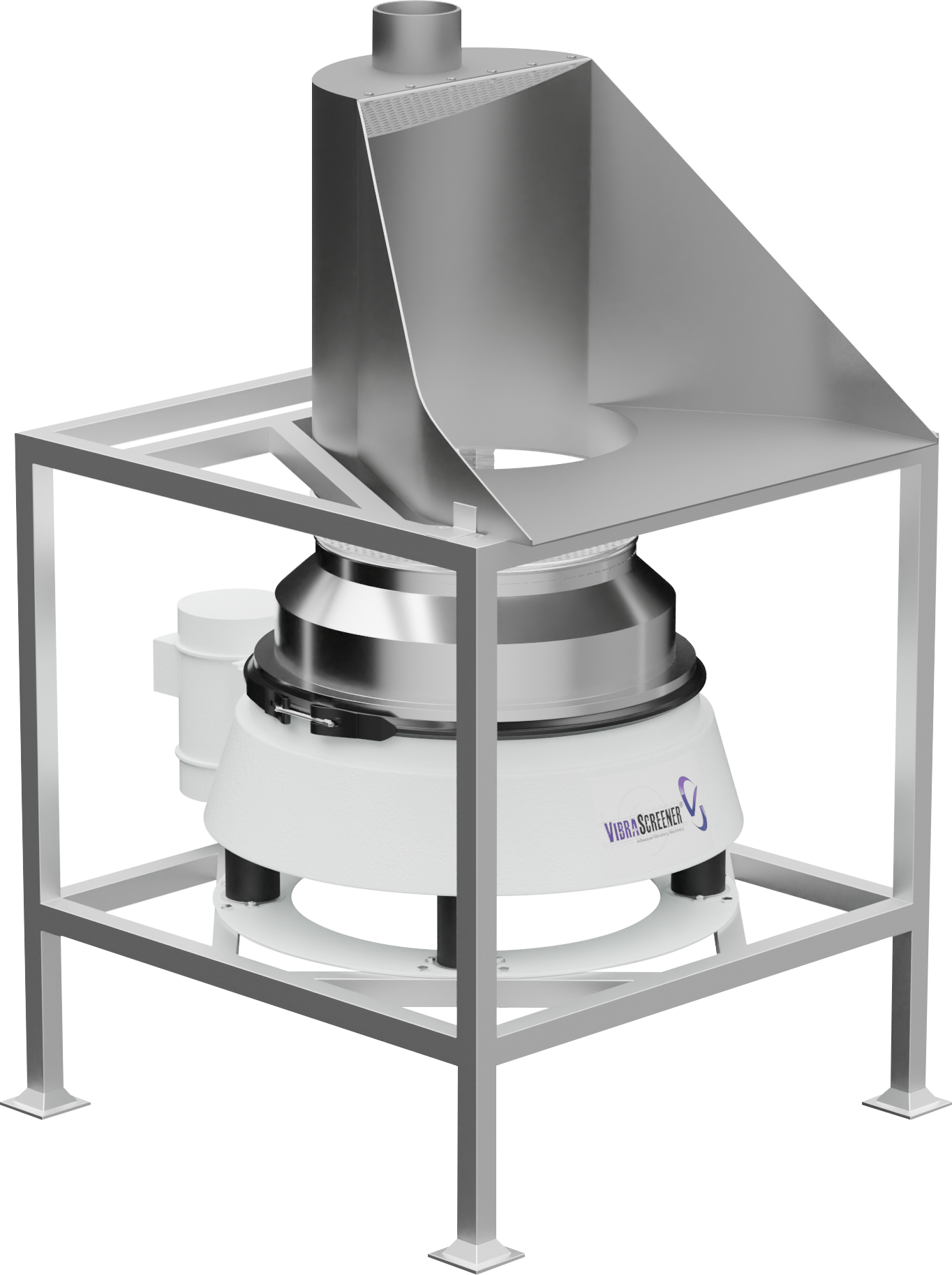

Vibrating sifters are engineered to separate, classify, and remove unwanted particles from bulk materials. In food and beverage manufacturing, this means the ability to quickly sift out contaminants, lumps, or oversized particles from ingredients such as flour, sugar, spices, or even liquid slurries. By automating this process, manufacturers reduce manual labor, minimize the risk of human error, and ensure that only the highest quality materials reach the next stage of production.

Some key efficiency benefits include:

- Continuous Operation: Vibrating sifters are designed for 24/7 use, allowing for uninterrupted production runs and minimizing downtime.

- High Throughput: Their rapid vibration and precision screening capabilities enable the processing of large volumes of material in a shorter time frame.

- Easy Integration: Modern units are compact and can be easily integrated into existing production lines, reducing the need for major facility modifications.

Ensuring Product Quality and Safety

Quality control is non-negotiable in the food and beverage sector. Vibrating sifters provide a crucial checkpoint, ensuring that only materials meeting strict size and purity specifications move forward. This is especially vital for allergen management, preventing cross-contamination, and complying with food safety regulations.

Key quality advantages include:

- Consistent Particle Size: Uniform screening delivers consistent product texture and appearance, which is essential for consumer satisfaction.

- Contaminant Removal: Effective separation mechanisms capture foreign matter, safeguarding both the brand reputation and the end consumer.

- Sanitary Design: Most sifters are constructed from food-grade materials and feature easy-to-clean surfaces, supporting hygiene protocols and quick changeovers between product runs.

Flexibility for Diverse Applications

The versatility of vibrating sifters makes them suitable for a broad spectrum of food and beverage products, from dry powders and granules to wet mixtures and viscous liquids. Manufacturers can choose from a variety of screen sizes and configurations to match their specific process requirements. This adaptability extends to:

- Bakery Ingredients: Sifting flour, sugar, and cocoa powder for uniform doughs and batters.

- Beverage Production: Filtering fruit pulp, seeds, or undissolved solids in juice or dairy processing.

- Snack Foods: Separating seasonings or coatings to ensure even distribution and flavor consistency.

Streamlined Maintenance and Operation

Ease of maintenance is another significant advantage. Most vibrating sifters feature tool-free disassembly, making daily cleaning and periodic inspections straightforward. This reduces the risk of costly breakdowns and keeps production on schedule. Additionally, intuitive controls and automated monitoring systems allow operators to adjust settings quickly in response to changing production needs.

The Bottom Line for American Manufacturers

Adopting vibrating sifters has become a strategic decision for food and beverage manufacturers aiming to stay competitive in the American market. These machines not only automate and accelerate the screening process but also ensure that every product meets the highest standards of quality and safety. Their flexibility, reliability, and ease of use make them a smart investment for any production facility seeking to streamline operations and deliver consistent, high-quality products to consumers. As the industry continues to evolve, vibrating sifters will undoubtedly remain at the forefront of food and beverage manufacturing innovation.