When the time comes to hire a team to handle your sheet metal fabrication services, invest in a company that does it all for you. When you turn to a single source for the design and development of your components, you save time, minimize complications, and even save money. Of course, for this to happen, you must work with a skilled and capable provider, one with ample ability to work to meet your specific fabrication needs while also managing any limitations. Exploring the production capabilities of any fabrication provider is the first step in making this decision.

What Does the Company Offer?

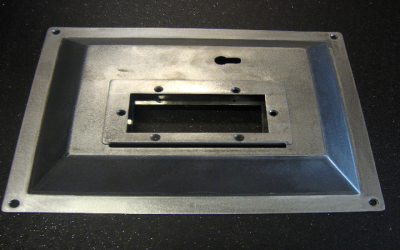

Learn as much as you can about the company you are hiring for sheet metal fabrication services. Some companies specialize in a specific industry, such as automotive or industrial. Others provide for any need. You may need a company with experience with more intricate or complex projects. A newer organization or one without the most advanced technology is likely to struggle with this type of application. You also want to learn about their technology – is it up to date, modernized, and capable of working with your current setup? Learn about the stamping and fabrication sizing options as well as the metal types they work with on projects. Also, consider any secondary services offered such as robotic welding or resistance welding. Choosing a single company to provide for these services can help to reduce your costs overall.

The more you know about the company, the better. Invest in an organization with the resources to help you throughout the development and completion of your project. Recognize that not all sheet metal fabrication services are equal, but those with ample dedication and modern technology are sure not help you achieve your biggest and most important goals.