Stainless steel is a very versatile metal. It combines malleability with certain desirable properties. Industries find a myriad number of uses for the product. Yet, no matter what the intent, many of the designs and products start in the most convenient form – sheet metal. In many instances, the required design and result specifies eh need for perforated stainless steel sheet.

What Are Perforated Stainless Steel Sheets?

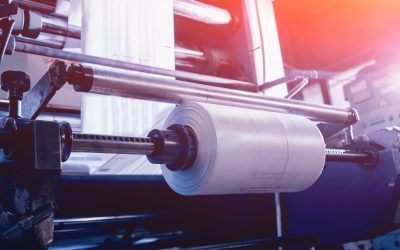

Sheet metal refers to thin, flat pieces of various gauges. These pieces are shipped to fabrication shops where they act as the basis for the work. They may arrive as coiled strips or, more commonly, flat pieces. This is the most common type of stainless steel metal available for fabrication work.

In order to produce perforated sheets, a company has to utilize specialized equipment. These are perforating presses. They punch holes by the thousands simultaneously into the material. The machines do so are programmable, capable of performing the required actions according to the exact specifications demanded by the customer. This allows fabricators to vary the distance between holes. It can also vary the pattern producing straight lines or staggered rows of holes. By using the right machinery, a fabricator can customize the designs to address diverse industrial needs. The entire process can take only minutes to complete.

Why Sheet Metal Requires Holes

Perforated stainless steel sheet metal finds use in various industries. They require this type of fabricating work to meet both functional and decorative needs. They may require the perforated sheet metal for the production of dishwasher strainers. The metal may also satisfy the architectural design of a sound proofed ceiling. Them perforated metal may be employed by:

* Architectural design: acoustic panels, lighting fixtures, sound-absorbing structures, stair treads and wall panels

* Aerospace industry: fuel and air filters

* Appliance manufacturers: microwave screens and strainers

* Automotive industry: air filters, diffusers, muffler guards, oil filters and radiator grilles

* Food and beverage concerns: baking trays, coffee screens, fruit and vegetable juice presses and wine vats

* HVAC system producers: enclosures and ventilation

This is a small sample of the demand for perforated stainless steel sheets in industry.

Perforated Stainless Steel Sheet Metal

Stainless steel sheet metal provides the basis for many products. It varies in sizes, shapes and gauges. It you need a product capable of providing ventilation, sound reduction and drainage while being decorative, fabricators have the perfect answer. In the hands of the right fabricators, perforated stainless steel sheet metal leaves the shop punched in the exact specifications of size, and hole shape requested – ready to fulfill its industrial role.