When working on a tiling project, precision is essential. Whether you’re installing ceramic tiles in your bathroom or building a mosaic floor in your kitchen, the equipment you employ has a significant impact on the quality of the overall result. One such essential item is the tile cutting blade. This specialist blade cuts through many tile materials, including porcelain, ceramic, and natural stone, producing clean and accurate cuts. It offers a combination of strength and precision, which is critical when cutting hard, fragile materials like tiles. Without the proper blade, tiles might fracture or shatter, resulting in waste and uneven finishes.

Choosing the Right Cutting Blade.

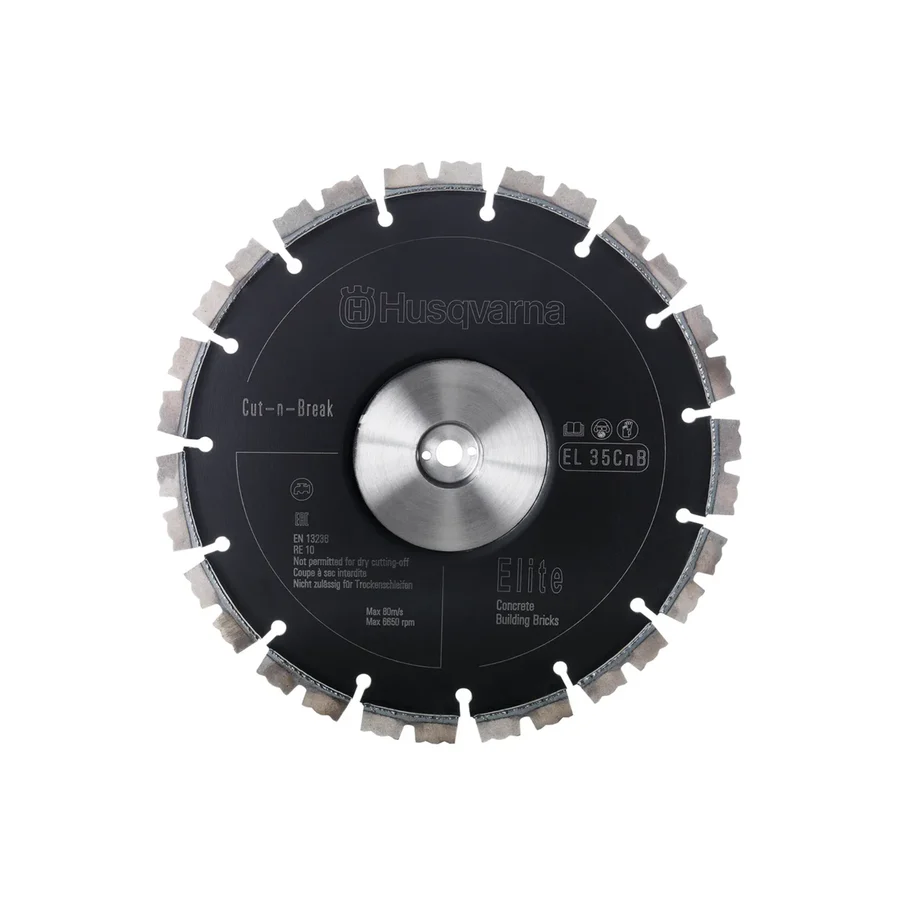

When choosing a blade for cutting tiles, one of the most important factors to consider is the tile material. Conventional blades can cut ceramic tiles, while specialized blades are necessary for porcelain or marble. Porcelain tiles, which are notorious for their hardness, require a high-quality diamond blade that can endure the tile’s density while providing smooth, clean cuts. Ceramic tiles, on the other hand, are typically easier to cut because they are not as resilient as porcelain. Blade type is another important consideration in your decision-making process. Tile cutting blades come in many styles, including continuous rim, segmented, and turbo. Continuous rim blades are renowned for producing smooth, chip-free cuts, making them excellent for fragile tiles and precision work. The size of the blade is also essential. Depending on the size of your tiles and the scope of your project, you might want a larger or smaller tile cutting blade. Smaller blades are sometimes more controllable, allowing for more control when performing precise or detailed work. Larger blades, on the other hand, are better suited to large-format tiles or tasks requiring rapid surface coverage.

Correct Use and Maintenance

Apply consistent pressure throughout the cutting operation to avoid driving the blade through the tile. Forcing a tile cutting blade can induce premature wear and overheating, which reduces its efficacy. Wet saws, which use water to cool the blade during the cutting process, are successful at increasing blade life by reducing heat accumulation and dust. It is particularly handy for cutting materials like porcelain or stone. Proper storage of the blade is equally vital. Keep your blades in a dry, safe area, away from moisture and inadvertent harm. Rust and corrosion can render even the best blades useless, so take care to maintain your blades correctly between uses. Cleaning the blade will help to keep it sharp. Remove any dust, debris, or residue after each usage to preserve the blade in excellent condition. A clean blade cuts more effectively and lasts longer.