Besides manufacturing new machines or fabricating parts, many machine companies offer services such as plasma cutting services to their clients. These services are useful in a few different circumstances. Keep reading to find out when it’s a good idea to contract with a company offering plasma cutting in addition to standard manufacturing.

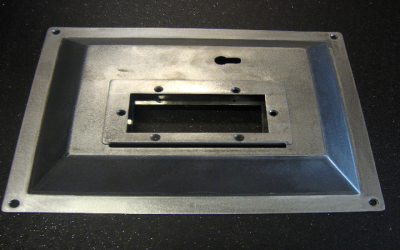

When You Need Precise Cutting and Shaping

If you are submitting an order that you know will need to be cut into precise shapes later, it makes a lot of sense to work with a company that conducts all of its services in-house. If everything from fabrication to plasma cutting services is done under one roof, you save time on shipping and finding partners, and you save on costs.

When placing a fabrication order, it pays to think ahead and contact a company that does cutting services as well if you know you will need them.

When You Need to Cut a Lot of Material

One of the benefits of plasma cutting services is that plasma cutting is one of the most efficient ways to cut into metal. The process is automated, which means that even large orders are finished quickly. There is a minimum waste of material thanks to precise designs and the lack of a start cut. While this may not make much of a difference for smaller orders, on larger orders it adds up.

When your metal sheets or other materials will need to be precisely shaped, plasma cutting is one of the best ways to do so.