CNC technology is rapidly taking over the operation of many different types of equipment and machinery in machining, welding and other forms of metalwork and fabrication. Companies in Cleveland believe it is an integral component of any shop seeking to improve its capabilities, market base, and production levels. Among the various types of equipment utilizing CNC are cutting equipment. CNC plasma cutting tools offer their operators various advantages over traditional cutting equipment.

Plasma Cutting

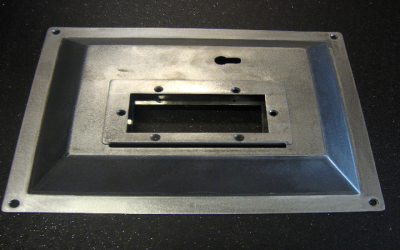

Plasma cutting torches cut metals of various types. Hand-held plasma torches are excellent tools for cutting but lack the accuracy and edge quality capabilities of CNC plasma cutting torches. While hand-held torches can slice quickly and efficiently through sheet metal, they cannot produce the preciseness many companies require. A CNC plasma system consists of a plasma torch and a table. CNC uses

Advantages of CNC Plasma Cutting

Fabrication shops are turning to CNC to help them improve the capabilities while reducing costs. Cleveland professionals cite the following as representing the most common advantages of using a plasma system:

* Ease of Use: A company does not need to hire someone with extensive specialized training to operate the CNC cutter. Moreover, they do not need complex adjustments.

* Efficient: Plasma cutters cut much quicker than other forms of cutting machinery e.g. oxy-fuel cutters

* Precision and Accuracy: Plasma cuts are sharp and neat. They produce superior cuts than other types of cutting equipment do resulting in eliminating further finishing processes

* Versatile: CNC plasma cutters can slice through a variety of ferrous and non-ferrous metals of varied lengths Ability to slice through various thicknesses

* Speed: The systems operate at high speeds. In addition, plasma systems do not need preheating, therefore the torch can begin cutting immediately, reducing time

* Safety: The downward draft or exhaust system pulls the smoke away from operators

The advantages of using a CNC plasma cutting system are sure to continue to incite fabricators in Cleveland and elsewhere to install them.