Electromagnetic flow meters are also known as mag meters or magnetic flow meters. These meters work for many industries. Such industries include water management, mining, processing, life sciences, and food processing industries.

These meters are more accurate and precise, thus their growing popularity. According to market research companies, the electromagnet flow meter market will grow at 6% CAGR from 2019 to 2027.

There are extensive industrial applications for electromagnetic flow meters. Such industrial use has led to a spike in the manufacture of these meters.

What are Electromagnetic Flow Meters, and How Do They Work?

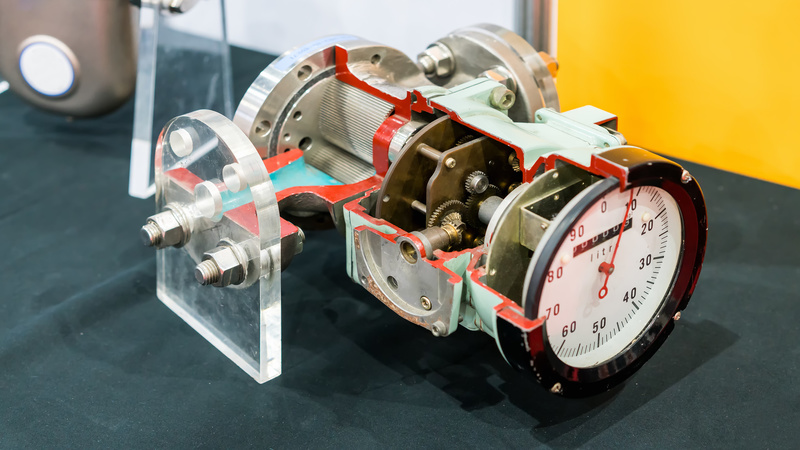

These are meters that detect flow using Faraday’s law of induction. Inside the meter, a transmitter and sensor make flow measurement possible.

The sensor is in charge of measuring the voltage as the fluid flows through the pipe. The transmitter then picks up the voltage, converting it into a flow measurement. This measurement is finally transmitted to a control system.

Benefits of Electromagnetic Flow Meters

Accuracy and efficacy are vital in industries that use electromagnetic flow meters. Compared to previous meter versions, electromagnetic flow meters are up to date with the latest technologies.

For maximum functionality, find the best electromagnetic flow meter manufacturer in India. This way, you will have zero issues with your meter.

You will also experience the following benefits:

• These meters do not have obstructions (because of their design)

• Electromagnetic flow meters are unaffected by temperature, pressure, or viscosity of the fluid

• The meters can detect contaminants such as air, bubbles, and solids

• There is no pressure loss with electromagnetic flow meters

• There are mechanical or moving parts (improves reliability)

• Electromagnetic flow meters are cost effective

• The meters are bi-directional

Selecting electromagnetic flow meters for your industry is recommended because of the range of liner materials. Additionally, electrode options and line sizes make applying these meters to different industries easier.

The electromagnetic flow design does not leave obstructions in the pipe. As a result, these meters can accommodate sanitary liquids and abrasive or highly corrosive fluids.